-

Brushless DC Motor

-

Brushless Permanent Magnet Motor

-

Gearbox Brushless Motor

-

Gearbox Stepper Motor

-

Hybrid Stepper Motor

-

Planetary Reducer Gearbox

-

Linear Stepper Motor

-

Frameless Servo Motor

-

Conveyor Roller Motor

-

DC Worm Gear motor

-

Stepper Motor Controller

-

BLDC Motor Driver

-

Integrated Stepper Motor

-

DC Brush Gear Motor

-

AC Servo Motor

-

Rod S****I purchased the 3-pack of the smaller steppers for my current ender 3 pro project. For my applications, they work perfectly. It's a great deal for quality motors, and I'm going to purchase another 10 packs.

Rod S****I purchased the 3-pack of the smaller steppers for my current ender 3 pro project. For my applications, they work perfectly. It's a great deal for quality motors, and I'm going to purchase another 10 packs. -

Sam N***These are great motors and they are very strong. They are operating quietly, and also need them to release their hold every time a move is complete.

Sam N***These are great motors and they are very strong. They are operating quietly, and also need them to release their hold every time a move is complete. -

Jim S**Please develop more low noise gearbox and with better prices, so we can sell your products to more clients and gain larger markets. Thank you.

Jim S**Please develop more low noise gearbox and with better prices, so we can sell your products to more clients and gain larger markets. Thank you.

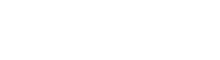

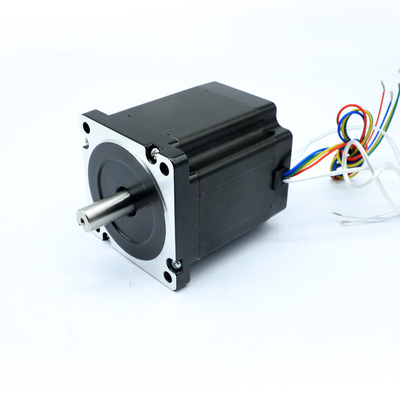

85HS with encoder HYBRID Motor for Industrial Applications 1.8° Step Angle 8.0 MH Inductance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Rated Current | 4.2A | Resistance | 0.8Ω |

|---|---|---|---|

| Diameter | 85mm | Type | Hybrid Stepper Motor |

| Voltage | 3.4V | Lead Wire | 4 |

| Holding Torque | 6.5N.m | Step Angle | 1.8° |

Product Description:

A Hybrid Stepper Motor is a type of stepping motor that combines the benefits of both open-loop and closed-loop motor control systems. It has a higher inductance than regular stepping motors and can provide more precise control, higher torque, and greater efficiency. The Hybrid Stepper Motor is characterized by its 8.0 MH inductance, 6.5N.m holding torque, 4 lead wires, and 4.2A rated current. It is a high-precision motor that offers smoother operation and better performance than other stepping motors. It is perfect for applications requiring precise motion control, such as robotics, automotive, medical, and industrial automation, as well as machine tools.

Features:

- Product Name: Hybrid Stepper Motor

- Inductance: 8.0 MH

- Type: Hybrid Stepper Motor

- Resistance: 0.8Ω

- Lead Wire: 4

- Diameter: 85mm

Technical Parameters:

| Parameter | Value |

|---|---|

| Type | Hybrid Stepper Motor |

| Diameter | 85mm |

| Voltage | 3.4V |

| Lead Wire | 4 |

| Step Angle | 1.8° |

| Holding Torque | 6.5N.m |

| Rated Current | 4.2A |

| Resistance | 0.8Ω |

| Inductance | 8.0 MH |

Applications:

HeTai 85HS Hybrid Stepper Motor is a perfect choice for precise motion control in a wide variety of applications, such as 3D printing, robots, CNC machines, security systems, and medical equipment. It features high torque, low inductance, and a step angle of 1.8°, making it an ideal replacement for traditional stepper motors. The motor has a winding resistance of 8.0 MH, a voltage of 3.4V, and comes with 4 lead wires. It is certified by CE, ROHS, and ISO and is available in minimum order quantity of 50. The motor is packaged in a carton with inner foam box and pallet for safe delivery at a competitive price.

HeTai 85HS Hybrid Stepper Motor is a reliable and efficient motion control solution that offers superior performance and accuracy. It is designed to deliver precise positioning, high torque, and low vibration, making it a perfect fit for various applications such as 3D printing, robotics, CNC machines, security systems, and medical equipment. The motor has a winding resistance of 8.0 MH, a voltage of 3.4V, and comes with 4 lead wires. It has a step angle of 1.8° and is certified by CE, ROHS, and ISO for quality and safety. The motor is available in minimum order quantity of 50 and is packaged in a carton with inner foam box and pallet for safe delivery at a competitive price. HeTai 85HS Hybrid Stepper Motor is the perfect choice for precise motion control, offering excellent performance and accuracy.

Customization:

HeTai 85HS

- Brand Name: HeTai

- Model Number: 85HS

- Place of Origin: China

- Certification: CE ROHS ISO

- Minimum Order Quantity: 50

- Price: USD

- Packaging Details: Carton with Inner Foam Box, Pallet

- Payment Terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram

- Lead Wire: 4

- Voltage: 3.4V

- Inductance: 8.0 MH

- Rated Current: 4.2A

- Type: Hybrid Stepper Motor

HeTai 85HS is a customized Hybrid Stepper Motor. It is certified by CE ROHS ISO and is designed to offer excellent performance. It features 4 lead wires, 3.4V voltage, 8.0MH inductance and 4.2A rated current. This product is available for order with minimum quantity of 50 pieces and can be shipped with carton and inner foam box, pallet.

Support and Services:

At XYZ, we provide comprehensive technical support and services to ensure our customers receive the best possible user experience with their Hybrid Stepper Motor. Our services include:

- 24/7 customer support via telephone, chat, and email.

- On-site installation and maintenance.

- Troubleshooting and technical advice.

- Upgrades and repairs.

- Replacement parts.

For any questions or inquiries about our Hybrid Stepper Motor, please don't hesitate to contact us.

Packing and Shipping:

- Hybrid stepper motors will be packed in a strong cardboard box.

- The box will be filled with foam to ensure the motor is not damaged during shipping.

- The motor will be shipped via a reliable courier service.

- The motor will be marked with a unique tracking number.

FAQ:

Q1:What is the Brand Name of Hybrid Stepper Motor?

A1:The Brand Name of Hybrid Stepper Motor is HeTai.

Q2:What is the Model Number of Hybrid Stepper Motor?

A2:The Model Number of Hybrid Stepper Motor is 85HS.

Q3:Where is the Hybrid Stepper Motor made?

A3:The Hybrid Stepper Motor is made in China.

Q4:What certifications does the Hybrid Stepper Motor have?

A4:The Hybrid Stepper Motor has CE ROHS ISO certification.

Q5:What's the Minimum Order Quantity of Hybrid Stepper Motor?

A5:The Minimum Order Quantity of Hybrid Stepper Motor is 50.![]()